Aluminum Tubing Phoenix, AZ

At United Aluminum we can supply heavy wall aluminum tubing in various shapes and sizes. Aluminum tubes are excellent candidates for most processing techniques and very good at corrosion resistance. So it’s ideal for projects that require use of a strong material, such as railings, hinges, bushing, and ornamental.

UNITED ALUMINUM

A BBB Accredited business since 1994!

We are a full service aluminum company dedicated to supplying the highest quality custom and standard shapes. We carry several high quality aluminum tubing in different shapes and sizes already in stock and available to you. We can also special order any shapes and sizes to fit any of your customized projects.

Please come in to our store or give us a call and we’re more than happy to assist.

Stocked Aluminum Tube Products

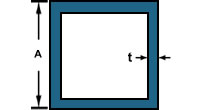

Aluminum Square Tube

Aluminum Square Tubing has square defined corners on both the inside radius and outside radius. They’re ideal for structural projects that require material such as trailers, frames, shelvers, and racks.

| A | t | Length |

| 0.750 | 0.125 | 10′ |

| 1.000 | 0.062 | 8′ |

| 1.500 | 0.062 | 8′ |

| 2.000 | 0.062 | 8′ |

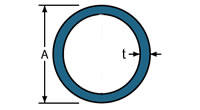

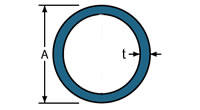

Aluminum Round Tube 6061T6

Aluminum Round Tubes are produced in several different alloys. Each alloy has specific uses and properties that make it unique. 6061T6 is the most commonly used alloy due to it wide variety of general properties.

| A | t | Length |

| 0.250 | 0.035 | 12′ |

| 0.375 | 0.035 | 12′ |

| 0.500 | 0.035 | 12′ |

| 0.625 | 0.035 | 12′ |

| 0.750 | 0.035 | 12′ |

| 0.875 | 0.035 | 12′ |

| 1.000 | 0.035 | 12′ |

| 1.125 | 0.058 | 12′ |

| 1.250 | 0.058 | 12′ |

| 1.375 | 0.058 | 12′ |

| 1.500 | 0.058 | 12′ |

| A | t | Length |

| 1.00 | .062 | 8′ |

Other Aluminum Tubing Products Available via Special Order

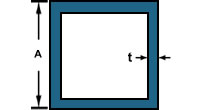

Aluminum Square Tube 6063T5

Aluminum Rectangle Tube is produced in 6063 and 6061 alloys. It has square defined corners on both the inside radius and outside radius. 6063 is the lower strength of the two alloys and is generally produced in thinner wall sizes but has better corrosion resistance and finishing qualities than 6061.

| A | t | Weight/Foot | Weight/piece |

| 0.500 | 0.063 | 0.130 | 3.120 |

| 0.750 | 0.063 | 0.208 | 4.992 |

| 0.075 | 0.125 | 0.374 | 8.979 |

| 1.000 | 0.062 | 2.800 | 6.720 |

| 1.000 | 0.125 | 0.524 | 12.576 |

| 1.250 | 0.062 | 0.354 | 8.496 |

| 1.250 | 0.125 | 0.674 | 16.180 |

| 1.500 | 0.125 | 0.824 | 19.776 |

| 1.750 | 0.125 | 0.974 | 23.380 |

| 2.000 | 0.125 | 1.126 | 27.024 |

| 2.000 | 0.250 | 2.100 | 50.400 |

| 2.500 | 0.125 | 1.426 | 34.220 |

| 3.000 | 0.125 | 1.725 | 41.400 |

| 3.000 | 0.250 | 3.300 | 79.200 |

| 4.000 | 0.125 | 2.326 | 55.820 |

| 4.000 | 0.188 | 3.400 | 82.560 |

| 4.000 | 0.250 | 4.500 | 108.000 |

| 4.500 | 0.188 | 3.892 | 93.408 |

| 5.000 | 0.125 | 2.926 | 70.224 |

| 5.000 | 0.188 | 4.342 | 104.200 |

| 6.000 | 0.125 | 3.530 | 84.720 |

| 6.000 | 0.188 | 5.240 | 125.760 |

| 6.000 | 0.250 | 6.760 | 162.240 |

| 8.000 | 0.188 | 7.050 | 169.200 |

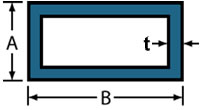

Aluminum Rectangular Tube 6063T5

Aluminum Rectangle Tube is produced in 6063 and 6061 alloys. It has square defined corners on both the inside radius and outside radius. 6063 is the lower strength of the two alloys and is generally produced in thinner wall sizes but has better corrosion resistance and finishing qualities than 6061.

| A | B | t | Weight/ft | Weight/piece |

| 0.500 | 1.000 | 0.065 | 0.240 | 5.760 |

| 0.500 | 1.000 | 0.125 | 0.374 | 8.976 |

| 0.750 | 1.500 | 0.125 | 0.600 | 14.400 |

| 1.000 | 1.500 | 0.062 | 0.354 | 8.496 |

| 1.000 | 1.500 | 0.125 | 0.674 | 16.180 |

| 1.000 | 2.000 | 0.062 | 0.428 | 10.272 |

| 1.000 | 2.000 | 0.125 | 0.824 | 19.776 |

| 1.000 | 3.000 | 0.125 | 1.130 | 27.120 |

| 1.000 | 4.000 | 0.125 | 1.426 | 34.224 |

| 1.000 | 6.000 | 0.125 | 2.025 | 48.600 |

| 1.250 | 2.500 | 0.125 | 1.050 | 25.200 |

| 1.500 | 2.000 | 0.125 | 0.974 | 23.380 |

| 1.500 | 2.500 | 0.125 | 1.125 | 27.000 |

| 1.500 | 3.000 | 0.125 | 1.274 | 30.576 |

| 1.500 | 6.000 | 0.125 | 2.174 | 52.180 |

| 1.750 | 3.000 | 0.125 | 1.350 | 32.400 |

| 1.750 | 3.500 | 0.125 | 1.500 | 36.000 |

| 1.750 | 4.000 | 0.125 | 1.650 | 39.600 |

| 1.750 | 4.500 | 0.125 | 1.800 | 43.200 |

| 1.750 | 5.000 | 0.150 | 1.950 | 46.800 |

| 2.000 | 3.000 | 0.125 | 1.426 | 34.224 |

| 2.000 | 3.000 | 0.250 | 2.700 | 64.800 |

| 2.000 | 4.000 | 0.125 | 1.726 | 41.424 |

| 2.000 | 4.000 | 0.250 | 3.300 | 79.200 |

| 2.000 | 4.500 | 0.125 | 1.876 | 45.024 |

| 2.000 | 5.000 | 0.125 | 2.025 | 48.600 |

| 2.000 | 6.000 | 0.125 | 2.325 | 55.800 |

| 2.000 | 6.000 | 0.250 | 4.500 | 108.000 |

| 2.000 | 8.000 | 0.125 | 2.930 | 70.320 |

| 2.500 | 8.000 | 0.125 | 3.076 | 73.824 |

| 3.000 | 4.000 | 0.125 | 1.985 | 47.640 |

| 3.000 | 5.000 | 0.125 | 2.325 | 55.800 |

| 3.000 | 5.000 | 0.188 | 3.440 | 82.560 |

| 3.000 | 6.000 | 0.188 | 3.891 | 93.384 |

| 4.000 | 6.000 | 0.125 | 3.080 | 73.920 |

| 4.000 | 6.000 | 0.250 | 5.700 | 136.800 |

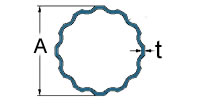

3003H18 alloy is most commonly used for drawn

tubing.

| A | t | Weight/Foot | Weight/piece |

| 0.750 | 0.063 | 0.158 | 3.160 |

| 0.750 | 0.125 | 0.288 | 5.760 |

| 0.875 | 0.125 | 3.460 | 6.920 |

| 1.000 | 0.062 | 0.219 | 4.380 |

| 1.000 | 0.083 | 0.281 | 5.620 |

| 1.000 | 0.125 | 0.413 | 8.260 |

| 1.000 | 0.125 | 0.576 | 11.520 |

| 1.000 | 0.250 | 0.693 | 13.860 |

| 1.250 | 0.065 | 0.285 | 5.700 |

| 1.250 | 0.125 | 0.530 | 10.600 |

| 1.250 | 0.188 | 0.736 | 14.720 |

| 1.375 | 0.188 | 0.841 | 16.820 |

| 1.500 | 0.065 | 0.345 | 6.900 |

| 1.500 | 0.125 | 0.648 | 12.960 |

| 1.500 | 0.188 | 0.911 | 18.220 |

| 1.500 | 0.250 | 1.178 | 23.560 |

| 1.750 | 0.065 | 0.412 | 8.240 |

| 1.750 | 0.125 | 0.730 | 14.600 |

| 1.750 | 0.188 | 1.084 | 21.680 |

| 1.750 | 0.250 | 1.385 | 27.700 |

| 2.000 | 0.063 | 0.443 | 8.860 |

| 2.000 | 0.125 | 0.870 | 17.400 |

| 2.000 | 0.188 | 1.270 | 25.400 |

| 2.000 | 0.250 | 1.650 | 33.000 |

| 2.000 | 0.375 | 2.251 | 45.020 |